Dr. Cheol-Woo Ahn, main a analysis staff on the Division of Purposeful Ceramics throughout the Ceramic Supplies Division on the Korea Institute of Supplies Science(KIMS), has developed the world’s first warmth dissipation materials. This materials reduces hydrophilicity via a chemical response that kinds a nanocrystalline composite layer and will increase thermal conductivity by controlling level defects. This course of happens throughout a easy sintering course of that doesn’t require floor remedy. KIMS is a government-funded analysis institute beneath the Ministry of Science and ICT.

Dr. Cheol-Woo Ahn, main a analysis staff on the Division of Purposeful Ceramics throughout the Ceramic Supplies Division on the Korea Institute of Supplies Science(KIMS), has developed the world’s first warmth dissipation materials. This materials reduces hydrophilicity via a chemical response that kinds a nanocrystalline composite layer and will increase thermal conductivity by controlling level defects. This course of happens throughout a easy sintering course of that doesn’t require floor remedy. KIMS is a government-funded analysis institute beneath the Ministry of Science and ICT.

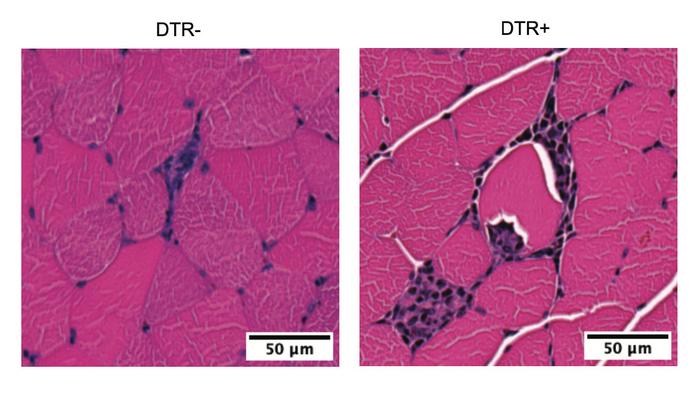

Typical alumina filler, extensively used for warmth dissipation, has limitations in enhancing thermal conductivity. Due to this fact, there’s potential in using magnesia, which affords low uncooked materials price and wonderful thermal conductivity and resistivity. Nevertheless, magnesia’s excessive sintering temperature of 1,800°C and its hygroscopic nature, which reacts with moisture within the air, have restricted its use as a thermal filler.

The analysis staff utilized components to create a skinny nanocrystalline composite layer throughout the sintering course of, forming a protecting layer that reacts with moisture. They succeeded in rising thermal conductivity by controlling defects via decrease sintering temperatures. This breakthrough is seen as overcoming the restrictions of current magnesia supplies and opening new prospects for thermal administration supplies in next-generation industries.

In recent times, with developments in high-tech industries, the miniaturization and multi-functionality of digital elements have posed important challenges for thermal administration. That is significantly evident within the high-capacity batteries of electrical automobiles and the elevated integration of digital elements, necessitating warmth dissipation supplies with excessive thermal conductivity to handle rising warmth density. Based mostly on electrical automobile gross sales projections, the marketplace for warmth dissipation supplies used within the thermal interface supplies of electrical automobiles is predicted to succeed in roughly 9.7 trillion gained in 2025. The outcomes of this analysis maintain important promise in addressing moisture response points and the excessive sintering temperatures related to current low-cost warmth dissipation supplies.

Dr. Cheol-Woo Ahn, the lead researcher acknowledged, “We have been capable of handle the moisture response challenge, which causes mixing with polymers, in an easy method via components within the manufacturing means of oxide ceramic fillers. We have now developed oxide fillers with excessive thermal conductivity by controlling defects. We anticipate that the developed low-cost, high-quality magnesia warmth dissipation filler will dominate the warmth dissipation ceramic materials market.”

The analysis acquired funding from the Ministry of Science and ICT via a basic undertaking at KIMS and a pilot undertaking for home manufacturing of magnesium (Mg) ceramic uncooked supplies from the Ministry of Commerce, Business and Power. The analysis findings have been revealed on December 14, 2023, within the prestigious journal Small Strategies (IF=15.367), with Dr. Hyun-Ae Cha, Senior Researcher at KIMS, as the primary creator. At present, the analysis staff continues to conduct follow-up analysis to reinforce efficiency, akin to rising the thermal conductivity of magnesia to the extent of nitride warmth dissipation ceramics. Moreover, KIMS is supporting mass manufacturing efforts by collaborating as a shareholder in SOULMATERIAL Co., Ltd., a analysis spin-off firm established via expertise funding.

————————————————————————-

###

About Korea Institute of Supplies Science(KIMS)

KIMS is a non-profit government-funded analysis institute beneath the Ministry of Science and ICT of the Republic of Korea. As the one institute specializing in complete supplies applied sciences in Korea, KIMS has contributed to Korean trade by finishing up a variety of actions associated to supplies science together with R&D, inspection, testing&analysis, and expertise assist.

DOI

10.1002/smtd.202300969

Article Title

Nanocrystalline Composite Layer Realized by Easy Sintering With out Floor Remedy, Decreasing Hydrophilicity and Rising Thermal Conductivity

Article Publication Date

14-Dec-2023

No Comments

Leave a comment Cancel